Introduction

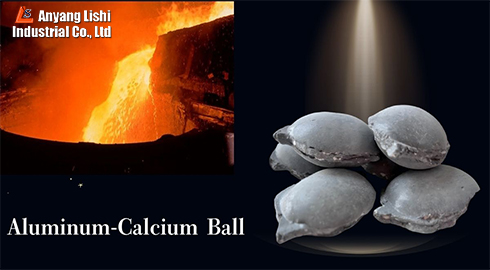

Aluminum calcium balls (Al-Ca balls) have emerged as an efficient composite alloy material in modern steelmaking, serving as both deoxidizer and desulfurizer to significantly improve molten steel cleanliness and support clean steel production. The cleanliness of molten steel directly determines the quality and performance of the final product. Deoxidation removes excess oxygen to prevent oxide inclusions, while desulfurization reduces sulfur to improve toughness and corrosion resistance.

Compared to traditional materials like pure aluminum or pure calcium, which face challenges such as low efficiency and high cost, Al-Ca balls combine aluminum and calcium to offer higher utilization rates and superior performance, gradually replacing conventional additives in steel plants.

Composition and Production

Al-Ca balls are mainly composed of aluminum (Al) and calcium (Ca). They are produced in spherical form, with diameters that can be tailored to plant requirements. The production process involves alloying aluminum and calcium in specific proportions, then shaping the mixture into balls.

This spherical design ensures uniform distribution and fast melting in molten steel. In some cases, silicon or other elements are added, creating Si-Al-Ca variants with enhanced functionality.

Role as a Deoxidizer

Oxygen in steel leads to alumina or oxide inclusions, which weaken material properties. Al-Ca balls improve deoxidation through a dual mechanism:

Aluminum reacts with oxygen to form Al?O?.

Calcium modifies these oxides into low-melting calcium aluminates that float up and are removed.

Compared with pure aluminum, the calcium in Al-Ca balls reduces the activity of Al?O?, preventing large, harmful inclusions. It also helps lower gas content such as hydrogen and nitrogen, reducing the risk of pores. In practice, Al-Ca balls are often added during the final deoxidation stage, ensuring higher efficiency, especially in high-strength and specialty steels.

Role as a Desulfurizer

Sulfur is harmful in steel, causing hot brittleness and corrosion. Calcium has strong affinity for sulfur, forming CaS that combines with slag and is removed. In Al-Ca balls, aluminum enhances calcium’s reactivity, improving desulfurization rates.

Studies show that using Al-Ca balls can reduce sulfur in steel to very low levels, which is essential for low-sulfur grades. They also improve molten steel fluidity, minimizing inclusion-related problems during continuous casting.

Advantages in Steel Plants

The use of Al-Ca balls provides multiple benefits:

Cost efficiency: Higher utilization than expensive CaSi wires, with less waste.

Wide applicability: Suitable for carbon steel, stainless steel, and alloy steels. Particularly effective in clean steel production.

Improved quality: Reduces inclusions, enhances mechanical properties.

Environmental benefits: Lower emissions, reduced dust, easier storage, and energy savings.

Conclusion

The application of aluminum calcium balls as deoxidizer and desulfurizer represents a key step toward efficient and clean steelmaking. They not only improve steel quality but also lower production costs, contributing to sustainable growth in the steel industry.

With continuous advances in metallurgy, Al-Ca balls and their variants are expected to see wider use, especially in the production of high-performance steels. Customized solutions for specific grades will further expand their role in the future. Partnering with LSFerroalloy ensures access to cutting-edge products, technical support, and reliable supply for next-generation steelmaking.